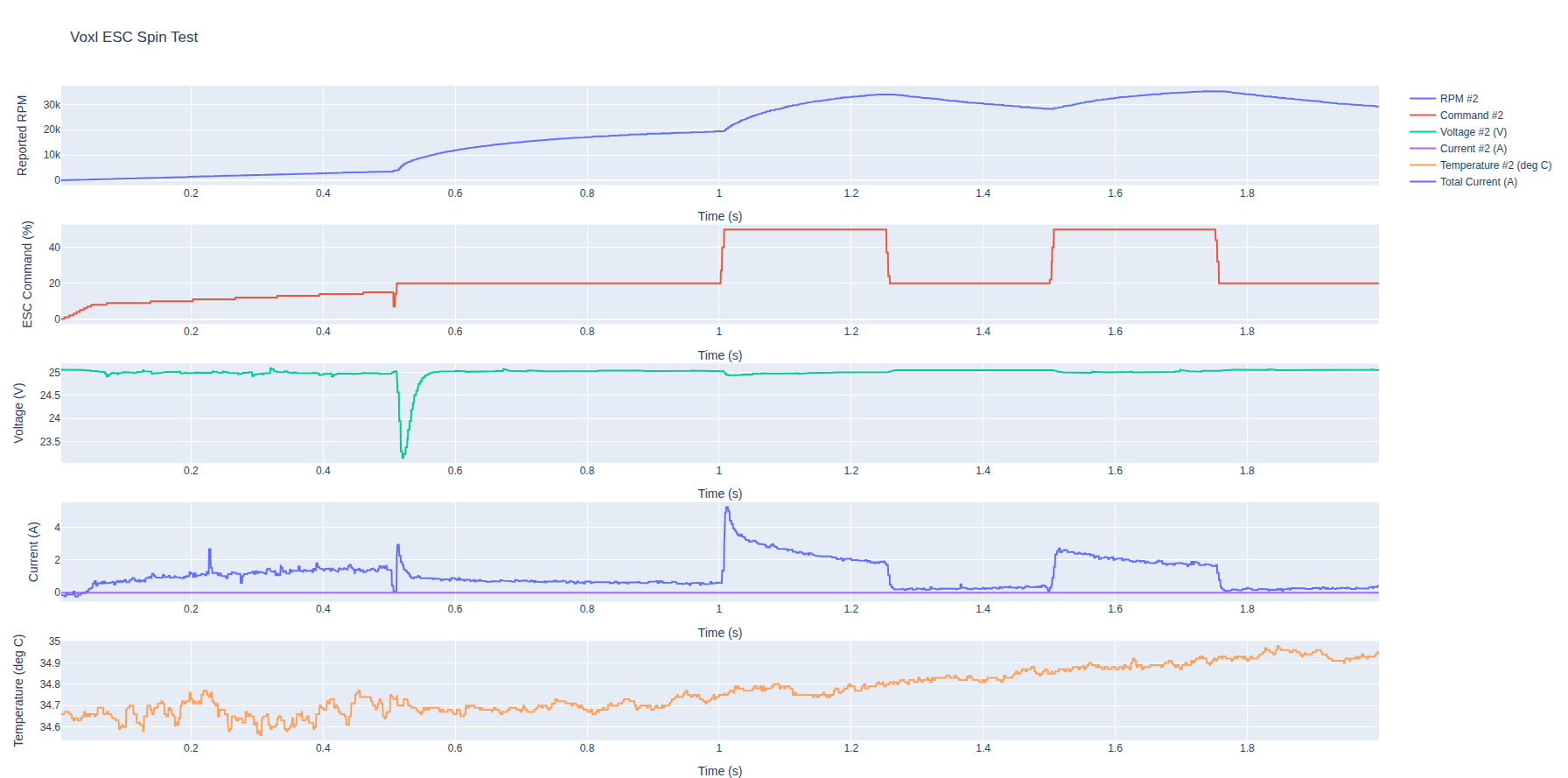

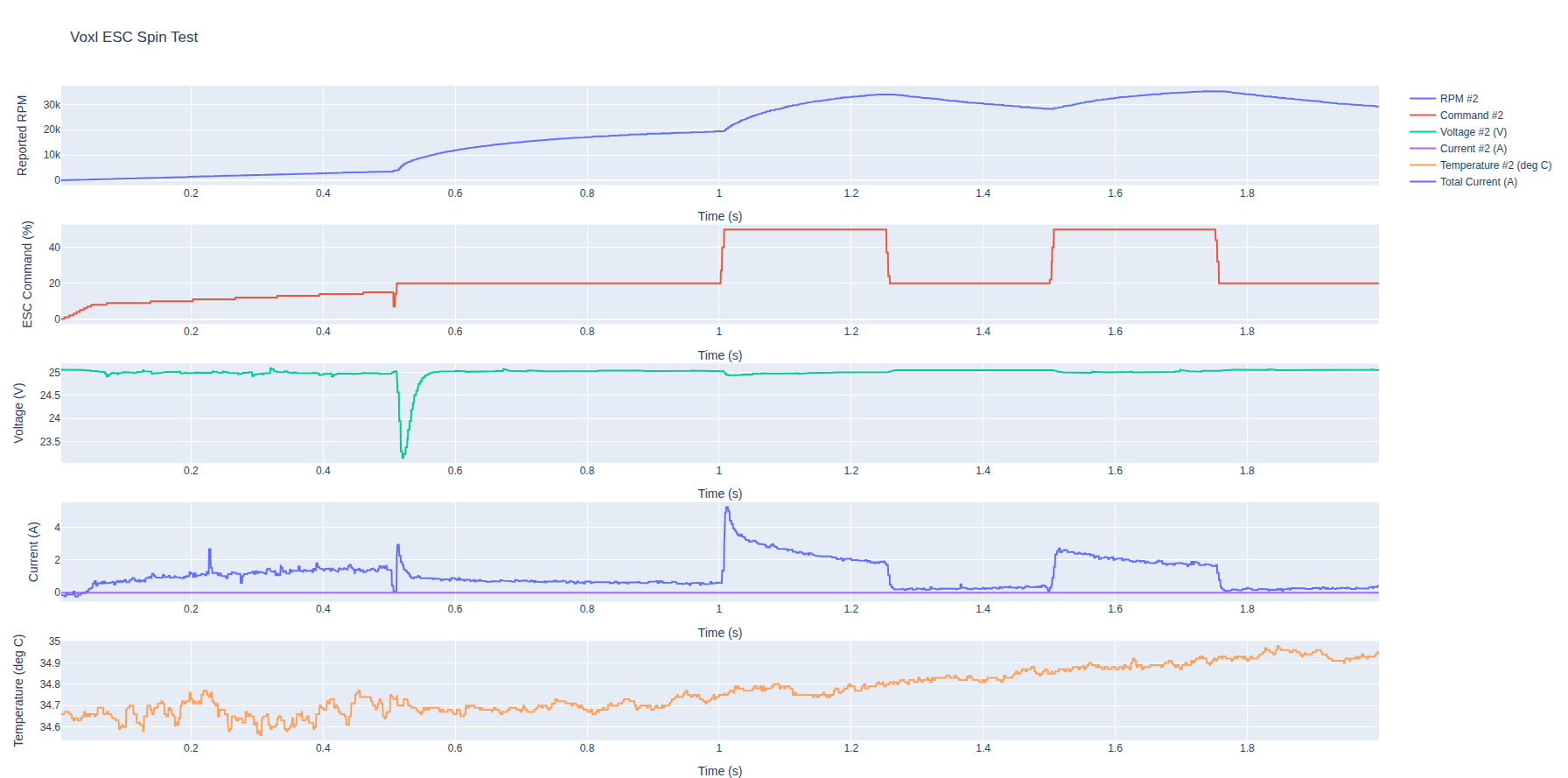

@austin-c , i just checked and actually we have an option to disable regen braking, it is just not available yet via a param. Here is the test result with same setup (no prop) with regen braking disabled. You can see that the motor takes a long time to coast down, but there is no regen voltage spike or regen current at all. If you application does not require rapid rpm change (high to low), then it will work fine.

We have not tested this in a while, but at some point we did testing for an application with a smart battery which did not like being re-charged with the regen current.

I will see if we can enable this via param or worst case scenario I can share the latest firmware with regen off.

Regarding your other questions:

- i don't think you can put enough capacitance to really absorb all the charge that needs to be stored.. You could do some basic calculations using the current spikes to see how much capacitance you would need, but it think it would be a LOT.

- regarding multiple TVS diodes, yes just connect an array of them in parallel, simply to distribute the energy (heat) across multiple diodes to prevent them from overheating (also can choose larger package, but they all would have to have same specs).

Also, since your motor is low kv, i just want to make sure you saw this document (you probably did, just double checking) : https://gitlab.com/voxl-public/voxl-sdk/utilities/voxl-esc/-/blob/master/voxl-esc-tools/doc/low_kv_motor_tuning.md

Actually the app note for low kv tuning was using the Tmotor MN4006 motor with even larger 15 inch propeller (see Tuning Example section). It should work fine with appropriate parameters, we can help tuning if you tell me the exact propeller.

motor MN4006-23 380kV, 18N24P winding configuration

12 pole pairs (24/2)

15-inch propeller MS1503

6S battery voltage

Alex