Motor issues when running ESC calibration

-

@Alexander-Saunders and @rdjarvis ,

the wall supply that can provide 3A is absolutely not enough to perform any motor testing, especially calibration. What happens if you try to do it, the wall supply will quickly reach its 3A limit and start decreasing output voltage, so the ESC cannot draw required power, so the calibration is useless (for lack of a better word). If you look at the voltage during the calibration stage, you will most likely see the voltage going into ESC will start dropping as soon as the power level will reach certain point at which the motor draws around 3A.

@Alexander-Saunders , i did not see the plot in your previous post - did you intend to attach an image of the plot?

Also, please provide a few more details to help me undrestand (i do have tmotor F2203.5 motor, so i can help you):

- what propeller are you using?

- what is the kV value of F2203.5 motor?

What could happen is that your propeller is too large for your motor or there are some tweaks we need to do to improve the ESC performance, which I can help with, but i need to know more details (above) and if you have any output from the terminal when the tests were running (it prints voltage, current, esc temperature, esc rpm, etc)

-

@Alex-Kushleyev Thank you for the fast reply!

T-Motor 2203.5 2850KV

3in 3052 Gemfan propOnly used wall supply for spin test, not calibration.

-

The values I sent was the output. I did not send the visual plot of the feed curve because we turned our attention to debugging why the motor was not behaving as inspected. We are ssh into the voxl when running the test. I haven't done the steps of moving calibration_results.html to plot yet.

-

@Alexander-Saunders , you just use adb or ssh to get the results html to your PC and open the html with any browser, it will show you the plot.

The results a0, a1, a2 tell very little information because it is just a data fit, it does not show underlying data points.

-

We cannot find the calibration_results.html.

We tried find / -type f -name "calibration_results.html"

and

locate calibration_results.html

find / -type f -name "*.html"No luck. Any suggestions on what directory the file would be in?

-

Using the script from this post: https://forum.modalai.com/topic/2522/esc-calibration I plugged in the one calibration test we ran before trying to troubleshoot the motor issues.

-

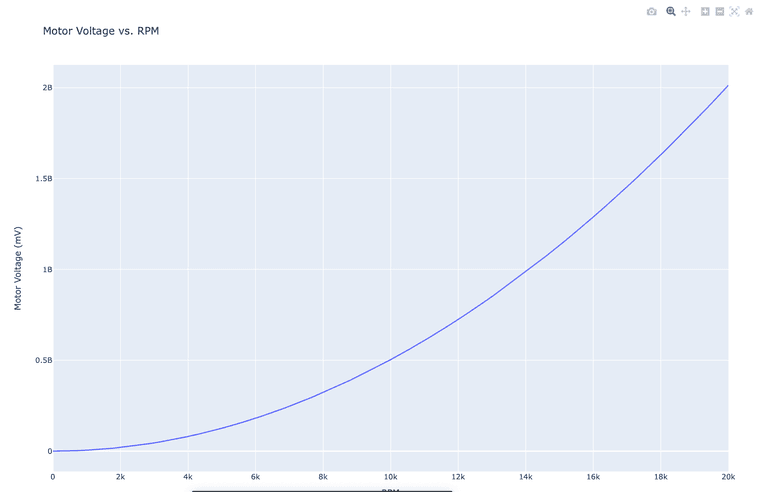

@Alexander-Saunders , like i said the plot does not tells us anything because it does not show the original data where something went wrong. also the plot i am looking for would be something like this:

If you are not seeing the calibration xml, then you probably used older version of the voxl-esc utils, you can get latest here

https://gitlab.com/voxl-public/voxl-sdk/utilities/voxl-esc/-/blob/master/

and showing where the html is saved:

https://gitlab.com/voxl-public/voxl-sdk/utilities/voxl-esc/-/blob/master/voxl-esc-tools/voxl-esc-calibrate.py?ref_type=heads#L275Do you have any data still available in the terminal where you ran the calibration, it would print the information received from the ESC (before the calibration is calculated)

-

@Alex-Kushleyev We do not have the data available.

-

@Alex-Kushleyev We have this:

INFO: ESC(s) detected on port: /dev/slpi-uart-2, baud rate: 250000

ID : 0

Board : version 42: ModalAi 4-in-1 ESC (M0138-1)

UID : 0x20333038524657120030001F

Firmware : version 39, hash e4f576a0

Bootloader : version 184, hash e1c038deID : 1 Board : version 42: ModalAi 4-in-1 ESC (M0138-1) UID : 0x20333038524657120054002A Firmware : version 39, hash e4f576a0 Bootloader : version 184, hash e1c038de ID : 2 Board : version 42: ModalAi 4-in-1 ESC (M0138-1) UID : 0x203330385246571200360037 Firmware : version 39, hash e4f576a0 Bootloader : version 184, hash e1c038de ID : 3 Board : version 42: ModalAi 4-in-1 ESC (M0138-1) UID : 0x203330385246571200300020 Firmware : version 39, hash e4f576a0 Bootloader : version 184, hash e1c038de -

@rdjarvis , ok that is fine.

What params do you currently have installed on the ESC? if you can share those, i can double check them.

After i confirm the params, i suggest using a new working motor and run the calibration with limited maximum power of 40 or 50 and see what the plots look like (low enough max power to avoid burn up).

Once we verify / fix any issues, we can run the calibration to higher power.

Please get the latest voxl-esc tools on your VOXL2 from : https://gitlab.com/voxl-public/voxl-sdk/utilities/voxl-esc/-/blob/dev

-

@Alex-Kushleyev /old/esc_params_modalai_4_in_1_revb_mn1804_2400kv_gemfan5040.xml

-

To add to Ryan response for params, we have the value of zero for the params kp and ki.

-

@Alexander-Saunders , OK, thanks, i don't see anything particularly wrong with using those params (even though the are from the old folder). I will do a test using these params and another similar motor just to check this.

I checked i only have the 1500kV version of your motor (i thought i had 2850, but cannot locate it at the moment). If i had the exact motor, i could test it. I will look again.

I just realized that the calibration script in the current state will not correctly show the total current on M0138 ESC (will show just zero). I need to make a small change to fix that.

one test that is similar to the calibration, but will show the current is the following:

./voxl-esc-spin.py --id 3 --power 40 --ramp-time 2.0 --timeout 2.5 --enable-plot 1 --cmd-rate 250This will spin id3 3 from 10 to 40 % power, it will take 2 seconds to ramp up the power and the test will end in 2.5 seconds and generate the plot (save to disk, same folder as the script).

40% power should be safe to start, if you can run that test with a working motor, i can take a look at the plot (html) -- you can send a screen shot of the html after you view it in your browser.

If the plot looks good, we can increase the maximum power in the ramp (gradually) and see how the motor performs. Please use the battery. If you see any abnormal behavior or unreasonably large current (in this test should definitely be less than 10A), you can terminate the test even faster using control-c.

-

@Alex-Kushleyev Thank you! We will test and get back to you.

-

@rdjarvis I am sorry, i made a mistake, the FPV ESC (M0138) has total current sensing on ID2, so please use the following command:

./voxl-esc-spin.py --id 2 --power 40 --ramp-time 2.0 --timeout 2.5 --enable-plot 1 --cmd-rate 250meanwhile, i will fix the calibration script to also use the total board current for the plots. The current is not used in the actual calibration procedure, but it is good for checking to make sure things look ok and there are no glitches.

Since you are using VOXL2, however, the total current will also include the VOXL2 current, which will mean the plot of current won't be as smooth.

Alex

-

The change was pretty easy, i enabled the board current to be used as ESC current for the calibration plot purposes. the change is on

devbranch ofvoxl-esc: (commit) . so you can use that latest code for testing. -

@Alex-Kushleyev wonderful, thank you, as always!

We will get to this as soon as we can for testing. Looking forward to the results.

RDJ

-

@rdjarvis, i found the correct motor 2850kV and just wanted to double check your propeller selection. 3in 3052 seems too small for this motor. Can you please confirm? Tmotor provides test data for 4in and 5in props for this motor : https://store.tmotor.com/product/f2203_5-fpv-motor.html . edit: they do also provide data for 3in (but 5 blade prop) - believe your propeller is tri-blade?

Either way is fine, just let me know and I will run the tests. I can start with the same params you did and see if i can reproduce the issue using FPV ESC. I have a 3076 propeller (tri-blade) which i can use for testing, which will be more aggressive than 3052 (i don't think i have 3052 available to test). I also have 3030.

Alex

-

@Alex-Kushleyev thanks for digging up the motor.

The 3in tri-blade prop works well with this motor, for our use case. We have more aggressively pitched props as well. Please test and send those params! That would be great. This will eliminate tons of trouble shooting.

Thank you,

RDJ -

@rdjarvis , I loaded the same params that you were testing and I was able to reproduce the issue.

The issue is that the old spin-up procedure is not working well for this particular motor and the ESC incorrectly synchronized with the motor phases (de-sync), resulting in incorrect motor control and motor overheating.

We recommend using our new sinusoidal spin-up procedure which is a lot more reliable.

I will make a new parameter file for the Tmotor 2850kV motor with a 3076 propeller and share with you as well as resulting plots for your reference.

Alex