90 degree & upside down sensor cables/adaptors!

-

Dear ModalAI,

While integrating your VOXL2 kit I found out some features we are missing and we have to do very intricate cable management to deal with it.I would find very interesting the option to "turn" the cameras 90 degrees with cables or some adaptors like the VOXL2 to Flex camera adaptor.

i.e.: The Camera extension flex but with the connector 90 degrees (left or right), not straightforward.

Also the extension cables could turn upside down the sensors, so when you connect the stereo sensors directly to the VOLX2, one can be looking down instead of both up.

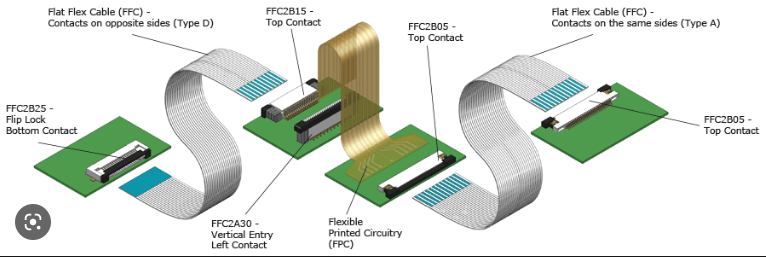

i.e.: for the extension flex, instead of the male connector on the upper part and the female connector on the lower part, both connectors at the upper part of the cable so the cameras faces opposite direction.Also, it can be beneficial to have a more "open" solution for cables, such as FFC/FPC cables for placing the sensors or think about the already solutions they provide but for your system:

With an adaptor people can route the sensors with more flexibility (not ensuring the proper function of the system of course). -

Thanks @Eloi for your suggestions.

We are actively working to improve our cables, cable design methods, customer communication on cables, and our image sensor flexes. It's a task we take seriously and want to improve upon.However, it is doubtful we can use ZIF style connectors for our platforms or be able to use COTS ZIF/FFC ribbon cables. They are the least vibe/shock tolerant of any connector class which require a lot of mechanical backing support to stay latched and engaged (and it must be movable to allow insertion and removal), thus adding weight, complexity, and size to the drone.

All of our image sensor flexes are also high-tech flex circuit assemblies, with power routing, specific ground plane control, EMI shielding, and high-speed impedance control, neither of which can be obtained from COTS FFC parts.

Hope that partly explains why we do not normally use FFC/ZIF parts.